In the era of rapid technological advancement, the supply chain industry is undergoing a transformative shift. Emerging technologies like Artificial Intelligence (AI), Blockchain, and the Internet of Things (IoT) are not just buzzwords—they are critical drivers of innovation, efficiency, and competitiveness in logistics and supply chain management. As businesses navigate the complexities of a global marketplace, leveraging these technologies is no longer optional but essential for success. In this blog, we explore how these cutting-edge technologies are shaping the future of supply chain management and how businesses can stay ahead of the curve.

The Role of AI in Supply Chain Management

Artificial Intelligence (AI) is rapidly becoming a cornerstone of modern supply chain management. By analyzing vast amounts of data and making predictive decisions, AI can optimize everything from inventory management to demand forecasting. Here’s how AI is transforming the supply chain:

1. AI-driven Demand Forecasting and Inventory Optimization

- Demand Forecasting and Inventory Optimization : AI-driven algorithms can analyze historical data, market trends, and external factors like weather or economic indicators to predict demand with remarkable accuracy. This helps businesses maintain optimal inventory levels, reducing both overstock and stockouts, leading to improved cash flow and customer satisfaction.

2. Automated Supply Chain Planning

- Automated Supply Chain Planning : AI-powered tools can automate complex supply chain planning processes, from procurement to production scheduling. This not only increases efficiency but also allows businesses to respond more quickly to changes in demand or supply chain disruptions.

3. Enhanced Decision-Making with Predictive Analytics

- Enhanced Decision-Making with Predictive Analytics : AI enables predictive analytics, helping supply chain managers make informed decisions based on real-time data. Whether it’s identifying potential bottlenecks, predicting delivery delays, or optimizing transportation routes, AI enhances decision-making across the supply chain.

Blockchain in Logistics: Building a Transparent and Secure Supply Chain

Blockchain technology, best known for its role in cryptocurrency, is making significant inroads into the logistics industry. Its ability to provide a secure, transparent, and immutable record of transactions makes it a game-changer for supply chain management.

1. Enhancing Transparency and Traceability

Blockchain creates a permanent, tamper-proof record of every transaction and movement within the supply chain. This level of transparency is invaluable for industries that require stringent tracking, such as pharmaceuticals or food safety, where knowing the origin of every component or ingredient is critical.

2. Streamlining Payments and Contracts

Smart contracts, powered by blockchain, can automate and secure payment processes, reducing the need for intermediaries. This not only speeds up transactions but also reduces the risk of fraud, ensuring that payments are made promptly and securely.

3. Improving Security Across the Supply Chain

With its decentralized and encrypted nature, blockchain enhances security across the supply chain. It protects sensitive data from cyber threats and ensures that all participants in the supply chain have access to accurate and verified information.

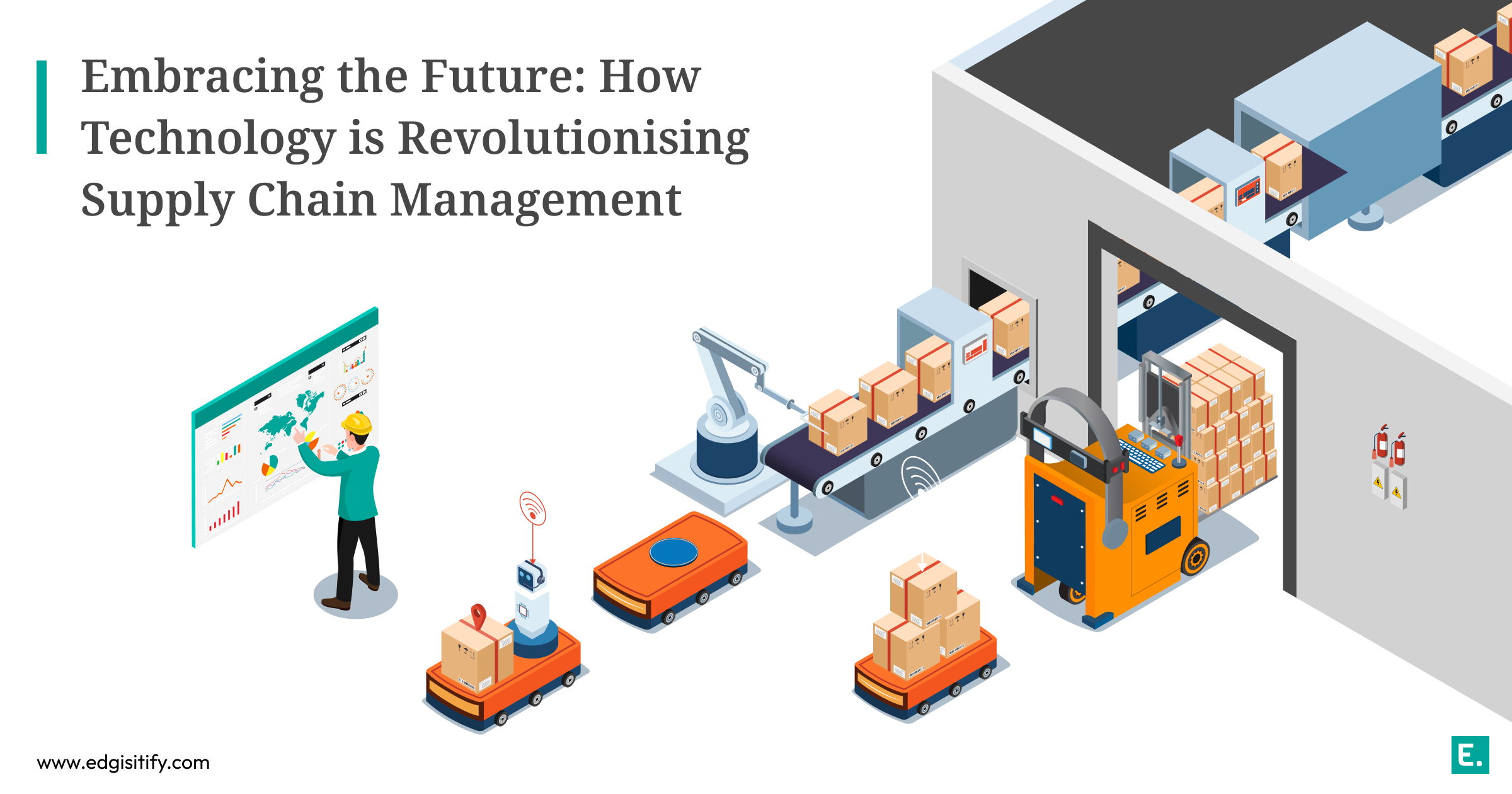

Warehouse Automation: The Key to Efficient and Scalable Operations

As the demand for faster, more efficient fulfillment grows, warehouse automation is becoming increasingly critical. From robotic pickers to automated storage and retrieval systems, warehouse automation is redefining how goods are stored, retrieved, and shipped.

1. Boosting Efficiency with Robotics

Robotics in logistics, particularly within warehouses, are revolutionizing how goods are handled. Automated guided vehicles (AGVs) and robotic arms can move, sort, and pack products far more efficiently than human workers, reducing errors and increasing throughput.

2. Reducing Costs with Automated Storage and Retrieval Systems (AS/RS)

AS/RS systems are designed to maximize storage space and automate the retrieval of goods. These systems reduce labor costs, minimize errors, and enable warehouses to operate more efficiently, even in limited spaces.

3. Enhancing Scalability

Automation technologies allow warehouses to scale operations quickly in response to market demands. Whether it's handling peak seasons or expanding into new markets, automated systems provide the flexibility needed to adapt to changing business needs.